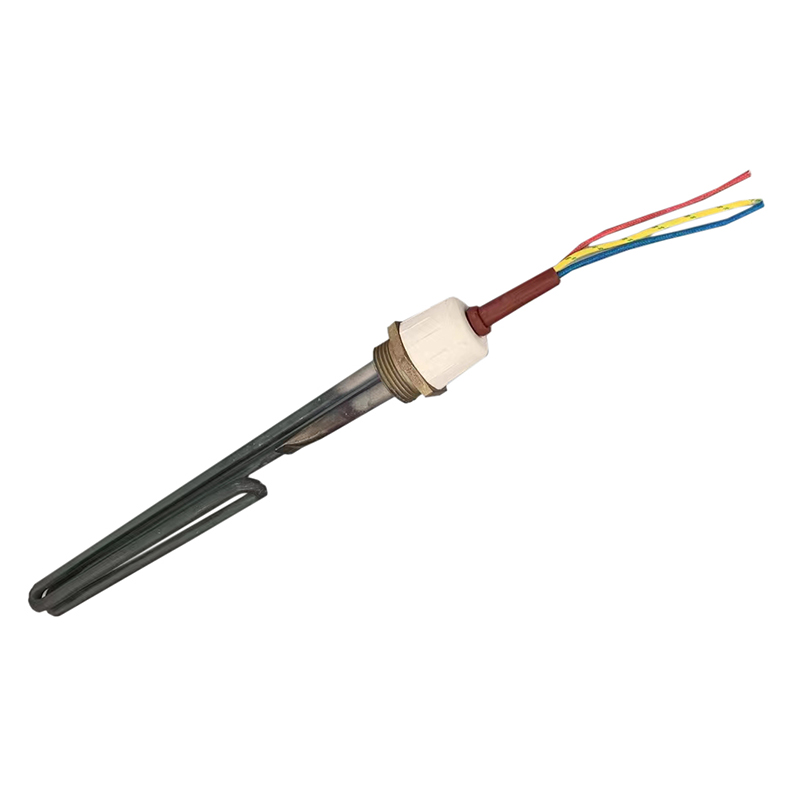

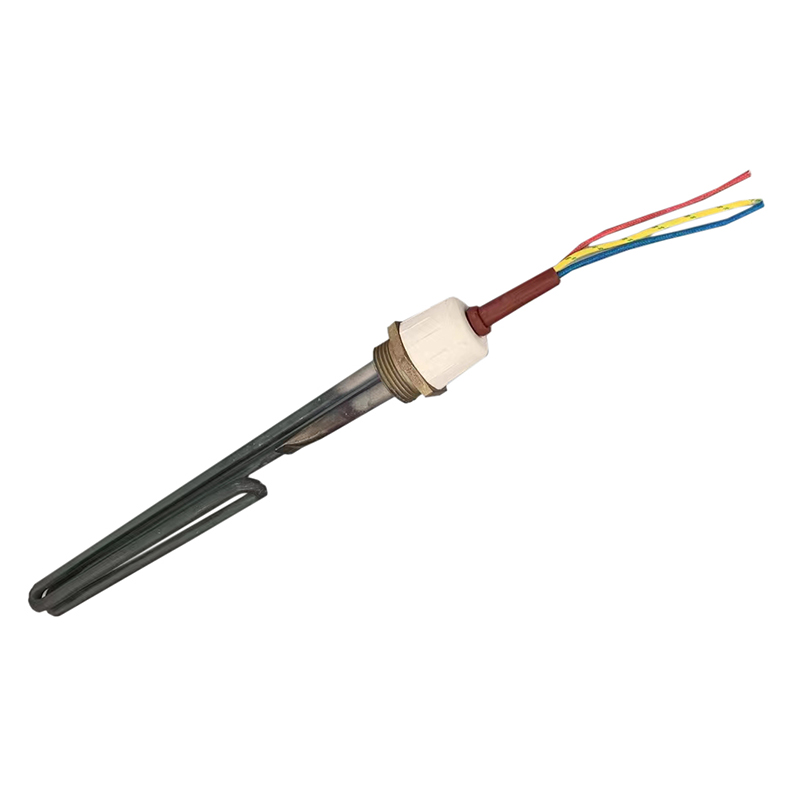

Durable INCOLOY 800 heating element for solar water heaters, designed for high efficiency, corrosion resistance, and long service life. Ideal replacement part for reliable water heating performance.

| What is the Difference Between INCOLOY and Copper Heating Element? | |||||

| Aspect | INCOLOY Heating Element | Copper Heating Element | |||

| Material | Nickel-based alloy (e.g., INCOLOY 800, 825). | Pure copper or copper alloys. | |||

| Corrosion Resistance | Excellent, especially in high-temperature and corrosive environments. | Moderate, susceptible to corrosion in acidic or harsh environments. | |||

| Thermal Conductivity | Lower than copper. | Very high, providing efficient heat transfer. | |||

| Durability | High; withstands extreme heat and corrosive chemicals. | Moderate; prone to oxidation and pitting over time. | |||

| Cost | Higher due to its superior performance. | Lower, making it cost-effective for general uses. | |||

| Applications | Industrial heaters, boilers, and chemical environments. | Domestic water heaters and low-corrosion settings. | |||

Incoloy 800 vs Copper Heating Elements – What’s the Difference?

In industrial heating applications, two common materials used for heating elements are Incoloy 800 and copper. Each has unique properties that make it suitable for specific requirements. Understanding their differences is essential for selecting the right material for reliable and efficient performance.

—

Incoloy 800 / 800H / 800HT

The chemical composition of Incoloy 800, 800H, and 800HT is very similar. All three alloys offer:

* Excellent resistance to reduction, oxidation, and nitriding medium corrosion.

* Strong resistance to alternating redox environments.

* High metallurgical stability during long-term high-temperature service.

These properties make them ideal for harsh industrial applications.

—

What is an Incoloy 800 Heating Element?

An Incoloy 800 heating element is a nickel-iron-chromium alloy element engineered for high-temperature and corrosive environments.

Key Features:

*Temperature Resistance:Performs reliably up to 1100°C without significant degradation.

*Corrosion Resistance: Outstanding performance in oxidizing, carburizing, and chemical-rich environments.

*Durability:Long service life, even under extreme conditions.

Applications:

*Boilers, industrial heaters, and heat exchangers

*Chemical and petrochemical industries

*Power generation plants

Advantage:

Incoloy 800 heating elements combine durability and superior corrosion resistance, outperforming copper and other materials in demanding, high-temperature applications.

Sorry, no posts matched your criteria.

You can contact us any way that is convenient for you. We are available 24/7 via fax, email or telephone.

WhatsApp us